No products

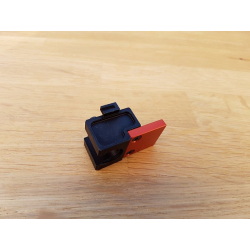

Hop-Up Chamber for AK

The Hop Up chamber for AK type airsoft guns is made of aircraft duralumin EN AW 7075, which ensures strength and lightness of the construction. The chamber is manufactured using CNC machining and has a 5 µm thick black protective anodizing finish. This chamber works best with CNC mechabox ver. III and can be expanded with a CNC support cube for easy reloading.

By buying this product you can collect up to 8 points.

View loyalty points rules.

Accessories

Hop Up chamber for AK type airsoft guns. The Hop Up chamber is made of EN AW 7075 aerospace duralumin, which has the strength of steel and the weight of aluminum, so it is suitable for these stressed parts. The Hop Up chamber is manufactured on a CNC machining centre and has a 5µm (0.005mm) thick black protective anodising finish.

Based on careful testing, the Hop Up chamber has been engineered for reliable charging and high performance. We changed the drilling depth and with a 20.1mm nozzle and Hop Up rubber 60 Shore, we achieved a stable performance of 16m/s over spring force. Feeding even heavy 0.43g ammo on both SEMI and AUTO was trouble free.

For a totally precise fit of the inner barrel, we equipped the Hop Up chamber with a special clamp nut, which is located in the front of the Hop Up chamber. The barrel is inserted with a Hop Up rubber band into the Hop Up chamber, secured with a regular plastic lock and finally screwed into the Hop Up chamber with a 10mm wrench. The clamp nut is made of aerospace duralumin EN AW 7075 and after screwing in lightly, it hugs the barrel which holds very firmly. The nut does not need to be tightened by force, just use moderate force, otherwise there is a risk of twisting the inner barrel in the Hop Up chamber. A sign of tightening is the reduction of the gap in the clamp.

The Hop Up chamber is best used in combination with a CNC mechabox version III, as both parts are designed so that the Hop Up chamber can be bolted to the mechabox with a screw, thus avoiding air loss and keeping the inner barrel on axis. The Hop Up chamber can also be used with a regular zincolite mechabox.

The Hop Up chamber can be expanded with a CNC support cube, which holds the Hop Up chamber in the body of the gun and makes reloading very easy. See accessories.

Pressure adjustment is made by pulling the control lever forward and backward as needed. The pressure roller is not included, but can be used from the original Hop Up chamber or use an upgraded silicone or Teflon pressure roller.

The Hop Up Chamber package includes:

- 1 piece Hop Up chamber for AK (material aerospace duralumin EN AW 7075, anodized).

- 1pc Control lever (material aerospace duralumin EN AW 7075, anodized).

- 1 pc Pressure lever with cut-out for standard pressure rollers (material aerospace duralumin EN AW 7075, anodized).

- 2pcs Screw M2,5 x 3mm (material steel 12050, chemically blackened).

- 1pc Screw M3 x 12mm (material steel strength 8.8, chemically blackened).

- 1pc Plastic lock for AK (material ABS plastic).

- 1pc Plastic pin (material ABS plastic)

- 1pc Rubber o ring (material vulcanized rubber).

- 1 pc Clamp nut (material aerospace duralumin EN AW 7075, anodized).

For the Hop Up chamber we recommend to buy a set of pressure rollers, a Hop Up rubber ring and, if necessary, a spare plastic lock or clamp nut.

The Hop Up chamber is delivered unassembled, i.e. disassembled into its individual parts.

The RetroArms Hop Up rubber band does not need to be sealed with Teflon tape as it has sealing tabs on the surface. For a smooth fitting of the Hop Up rubber band into the Hop Up chamber, it is advisable to use technical alcohol, which "lubricates" the Hop Up rubber band and evaporates after insertion into the Hop Up chamber and the Hop Up rubber band holds firmly.

For easy assembly of the pressure roller, we recommend "gluing" it to the pressure lever with Vaseline so that it does not fall out during assembly. Translated with www.DeepL.com/Translator (free version)